What Is Combined Heat And Power Systems – Effect of Different Coolant Mass Flow Rates on Turbine Blade Edge Seal Sealing Effectiveness in a First-Stage Gas Turbine Test Facility

Open Access Policy Institutional Open Access Program Special Issues Guidelines Editorial Process Research and Publication Ethics Article Processing Fees Awards Reviews

What Is Combined Heat And Power Systems

All articles published by are made immediately available worldwide under an open access license. No special permission is required for reusing all or part of an article published by, including images and tables. For articles published under the open access Creative Common CC BY license, any part of the article may be reused without permission, provided clear reference is made to the original article. For more information, visit https:///openaccess.

Doe Chp Ecatalog

The papers represent cutting-edge research in the field with significant potential for high impact. The feature article should be a significant original article that covers several techniques or approaches, provides perspective for future research directions, and describes possible research applications.

Fiction articles are submitted by scientific editors based on individual invitation or recommendation and must receive positive feedback from reviewers.

Editor’s Choice articles are based on recommendations from scientific editors of journals from around the world. The editors select a small number of recently published articles in the journal that they believe will be of particular interest to readers or will be important in a relevant field of research. The goal is to provide a snapshot of some of the most interesting work published in the journal’s various research areas.

By A.G. Olabi A.G. Olabi Scilit Preprints.org Google Scholar 1, 2, 3, * , Tabbi Wilberforce Tabbi Wilberforce Scilit Preprints.org Google Scholar 2, * , Enas Taha Sayed Enas Taha Sayed Scilit Preprints.org Google Scholar, 3, Khaled Elsaid Khaled Elsaid Scilit Preprints .org Google Scholar 5 and Mohammad Ali Abdelkareem Mohammad Ali Abdelkareem Scilit Preprints.org Google Scholar 1, 3, 4

Us Dept. Of Energy Grant To Advance Combined Heat And Power Systems In The Midwest

Mechanical Engineering and Design, School of Engineering and Applied Sciences, Aston University, Aston Triangle, Birmingham B4 7ET, UK

Received: July 19, 2020 / Revised: August 2, 2020 / Accepted: August 4, 2020 / Published: August 7, 2020

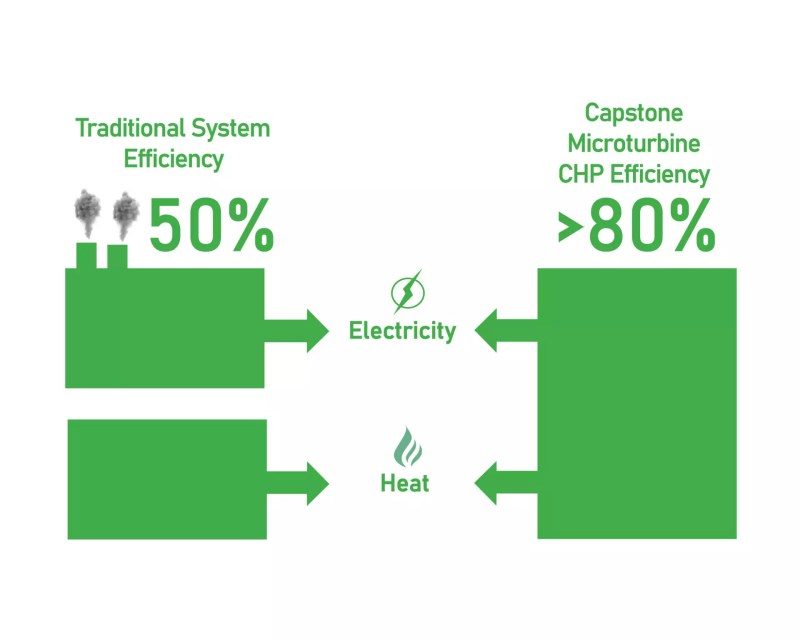

Combined heat and power (CHP) is the simultaneous or synchronous production of multiple usable energy sources, usually electricity as well as thermal energy, in a single and integrated device. The integration of combined heat and power systems into the modern energy market will solve the problems of energy shortage, global warming, as well as energy saving. This review emphasizes system design for fuel cell CHP technologies. Key among the components discussed was the type of fuel cell stack that could produce the maximum performance of the entire system. The type of fuel processor used was also noted to affect system performance along with longevity. Other components that were equally discussed were the power electronics. It was noted that heat and water management also affects the overall efficiency of the system. Reduced carbon dioxide emissions, lower electricity costs, and grid independence were some of the notable benefits associated with fuel cell combined heat and power systems. Despite these advantages, high initial capital cost is the main factor hindering its commercialization. Therefore, it is necessary to focus future research activities on the development of new and inexpensive materials for the development of the fuel cell, which will overcome the overall reduction of the entire system. Likewise, robust, systematic designs should be an equally active research direction. Other fuels aside, hydrogen should be explored equally. Proper risk assessment strategies and documentation will likewise expand and accelerate the commercialization of this new technology. Finally, public sensitization of the technology will also enable its adoption and possible competition with existing forms of energy production. In summary, the work showed that a proton exchange membrane fuel cell (PEM fuel cell) operating in lower temperature oriented cogeneration has good efficiency and is very reliable. A critical issue with these systems is the complexity associated with water treatment. This means that the balance of the plant will be significantly affected; similarly, the purity of the gas is very important in the operation of the system. An alternative to these systems are PEM fuel cell systems that operate at higher temperatures.

The search for a paradigm shift from the high dependence of fossil fuel due to its harmful effects on the environment has increased in the last few years [1, 2, 3, 4, 5, 6]. Factors such as unstable fossil commodity prices and depletion of the ozone layer are major factors encouraging the research community to consider alternative energy production environments. Increasing the efficiency of existing technologies using renewable energy sources such as waste heat recovery [7, 8, 9] and/or geothermal energy [10], solar thermal energy [11], solar PV [12, 13], hydroelectric energy [ 14, 15], biomass energy [16, 17] and wind energy [18, 19] have attracted much attention due to their environment-friendly nature. The main issue related to the high dependence of energy on renewable sources is related to interruptions in the energy production process [20, 21]. One of the ideal energy carriers for stationary purposes is hydrogen [22, 23]. It is also useful for other applications related to hydrogen transport [23]. The use of hydrogen for these purposes is considered very cheap, especially for large-scale purposes as well as in applications for energy storage for longer periods of time [24, 25]. Energy density is another added advantage of hydrogen. The promotion of renewable energy sources through a strong energy storage method encourages their growth, which will significantly reduce GHG emissions [26, 27, 28, 29]. The advantage of reducing greenhouse gas emissions can be noted in systems using hydrogen [29]. For example, hydrogen-based cogeneration systems obtained through natural gas steam reforming to power fuel cells can still minimize carbon emissions as well as nitrogen oxides (NOx) [30]. Zero emissions can be achieved by producing hydrogen through renewable media. In the fuel cell, the chemical energy of the fuel is instantly converted and generates electricity with a fairly good actual energy efficiency of up to about 55%, depending on the high heating value (HHV) of hydrogen [ 31 , 32 ].

Advantages And Disadvantages Of Combined Heat And Power Systems

Several types of fuel cell technologies are classified primarily based on operating temperature, membrane type, fuel or application [33, 34, 35, 36, 37, 38, 39, 40, 41]. Proton exchange membrane fuel cells (PEMFCs) have been widely recognized as promising technologies among various types of fuel cells [42, 43, 44, 45, 46, 47, 48]. PEMFCs are ideal for stationary, transportation, and auxiliary applications [37, 49, 50, 51, 52].

PEMFCs have several advantages over traditional power systems, such as very fast (less than 30 s) start-up [53, 54, 55], relatively low operating temperature, high electrical energy efficiency, and fast response [56, 57, 58, 59]. It is important to recognize that a high amount of thermal energy is also produced due to the operation of the proton exchange membrane, which is about 45-60% of the total energy content of hydrogen [60, 61, 62].

Low-temperature fuel cells are designed to operate between 60 and 80 °C to avoid any overheating that may cause dryness, which can degrade overall cell performance [ 63 , 64 , 65 ]. To increase the lifetime and efficiency of proton exchange membrane fuel cells, the heat generated must be removed.

Considering the amount of heat produced during PEMFC operation, heat recovery from PEMFC systems becomes an interesting concept to provide a new technique to increase the efficiency of cells, reduce their operating costs and minimize greenhouse gas emissions. The heat from PEMFCs can be used for low-temperature heating, such as room heating and domestic hot water, which require low-grade heating [ 66 , 67 , 68 , 69 , 70 , 71 , 72 ]. Several researchers have shown that the performance of a PEMFC combined heat and power (CHP) configuration can be increased to about 60–90% by absorbing the heat of the fuel cell [73].

How To Find Savings By Optimising Your Chp Plant

Heat produced from a fuel cell stack can also be harvested to control sorption cooling processes [74, 75, 76]. In addition, heat from the PEMFC stacks was also used to improve the hydrogen discharge rate of the metal hydride (MH) canister, as well as to preheat the inlet air. It is ideal for preheating the incoming air as well as hydrogen, especially in cold conditions [77]. In general, the concept of waste heat recovery has been mainly used for several years [77, 78, 79]. In addition, the possibility of using waste heat in fuel cell systems is being investigated, and scientists have paid great attention to increase their overall energy conversion efficiency, especially in recent years [80, 81, 82]. This review presents the latest trends in fuel cell heat and power fusion and critically reviews the key parameters hindering their commercialization. The components of fuel cell combined heat and power systems are thoroughly discussed, and their advantages and disadvantages are clearly defined. The following sections in this report will further explore fuel cell classifications based on combined heat and power performance characteristics as well as material composition. This will be the basis for the study

Combined heat and power chp, combined heat and power engine, combined heat and power plant, combined heat and power manufacturers, combined cooling heat and power, combined heat and power chp systems, combined heat and power unit, combined heat and power systems, combined heat and power generator, combined heat and power, micro combined heat and power, combined heat power systems