Cogeneration In Las Vegas’s Educational Institutions: Maximizing Energy Efficiency – Conventional water heaters are often thermodynamically wasteful because burning fuel at temperatures higher than 2500°F produces only a low level of energy ¬– hot water at 150°F to 200°F. With systems that burn natural gas (or propane) to heat water, this can mean excessive energy consumption, especially when combined with purchasing electricity from the utility company.

Through cogeneration, combustion at high temperatures produces both hot water and valuable electricity. Thermal performance is comparable to conventional water heaters, but in addition, 26% of fuel energy is converted into high-quality electricity. Combined electrical and heating efficiency is 83%. Utilization of the fuel’s energy potential, both high and low, is maximized.

Cogeneration In Las Vegas’s Educational Institutions: Maximizing Energy Efficiency

In this system, gas is burned in an efficient internal combustion engine designed for long-term industrial use. The engine drives a generator to produce electricity while simultaneously producing hot water from the engine’s waste heat. Thus, the cogeneration module can produce electricity and hot water only for the price of purchased electricity.

Power Cogeneration Performance & Comparative Analysis

Controlled Air, Inc. can offer cogeneration units ranging in size from 30 kW to 650 kW. Applications include hospitals, schools and colleges, athletic clubs, swimming pools, hotels and motels, apartments and condos, and food and beverage environments.

©2020 Controlled Air, Inc. Branford, CT. 203-481-3531. @ . Lic # CT S1 302788 / RI R/M1 & P/M 00007776Eastern Michigan University, ENGIE Services USA launches new cogeneration system that will provide more than 90 percent of the University’s electricity and heat The new unit will reduce the University’s carbon footprint while achieving net annual energy savings of 2.8 million dollars

A cogeneration system uses natural gas to drive a turbine, which produces electricity and heat from the exhaust air stream, producing electricity and heat from a single fuel source.

YPSILANTI – On Feb. 9, at noon, Eastern Michigan University “flipped the switch” to symbolically launch a new campus energy center, representing a dramatic change in the way energy is delivered across the EMU campus by reducing utility costs and greenhouse gas emissions .

Cogeneration Examples Across Industries

Shortly after 12:15 p.m., the University activated its new 55-ton, energy-saving cogeneration unit, which will supply approximately 98 percent of the heat and 93 percent of the electricity to Eastern’s 800-acre campus. Cogeneration is a combined heat and energy system that uses one fuel source, in this case natural gas, for the simultaneous production of electricity and thermal steam.

The first phase of construction on the project occurred when a new 55-ton turbine was installed in EMU’s Central Heating Plant using a 500-ton crane last summer. With a project cost of $19.6 million, the new cogeneration system replaces a 29-year-old cogeneration system. generating unit that ceased operations in April 2016. The older, less efficient unit supplied about 50 percent of EMU’s electricity and heat. The project will achieve annual net energy savings for the University of more than $2.8 million, or more than $50,000 per week, generating a return on investment in just under nine years.

How much environmental savings will result? The new cogeneration unit will create an annual reduction of 21,305 tons of carbon dioxide (CO2), which is equivalent to:

Eastern has partnered with national energy partner ENGIE Services. USA, headquartered in Oakland with regional offices in Michigan, on the project. ENGIE has worked with Eastern in the past, including helping to upgrade residence hall and dining facilities that have helped the University meet its environmental and energy conservation goals. Please watch the video that discusses the partnership in detail.

What Is A Cogeneration Plant? An Intro To Chp Systems

From left: James Smith, President of EMU; Ken Hedrick, ENGIE Director of Business Development; Leah Vandlandingham, EMU Student Department Sustainable Director; and James Webb, Chairman of the EMU Board of Trustees.

“marks a physical milestone for Eastern Michigan University,” said President James M. Smith. “Our new cogeneration system will significantly reduce our utility costs and at the same time have a great impact on the environment. On an individual level, the new system is far more efficient and resilient, meaning improved comfort in our learning environment for students, faculty and staff at Eastern.

“This project is part of our long-term efforts to identify new and innovative ways to reduce costs and improve the overall financial position of the University. Our work on this project arouses considerable interest, both from a financial and an environmental point of view.”

“Our long-term energy program with Eastern Michigan University represents the best kind of partnership – working with a dedicated, regional leader who is committed to harnessing clean energy to maximize the positive impact on their community,” said John Mahoney, president and CEO of ENGIE Services USA.

Solved Question 1 Consider A Cogeneration Power Plant That

“The new cogeneration system that will power the EMU Energy Center is a historic campus improvement that will have a positive financial, environmental and human impact on generations of graduates to come. ENGIE Services U.S. is proud to partner with EMU as it continues to set the bar for other higher education institutions across the country that are moving toward cleaner, more efficient forms of energy.”

In addition, upgrades within Central Heating represent a special learning opportunity for students attending EMU’s Faculty of Technology. ENGIE’s education team worked with university faculty to introduce an internship program that uses cogeneration technology as a real-world learning opportunity. During the spring and fall semesters of 2017, two students shadowed engineers and construction managers on site to gain hands-on knowledge through direct, hands-on experience.

In the spring of 2009, Eastern identified two key goals the University wanted to achieve during the renovation of four dorms and two dining halls: Make the space more efficient to work in and more comfortable for students and faculty. With the help of ENGIE Services U.S., EMU made major facility upgrades that resulted in several million dollars in energy cost savings over the life of the program.

After completing a comprehensive plant upgrade during a successful first phase of operation, EMU re-teamed with ENGIE in autumn 2016 to improve the performance, reliability and efficiency of its central heating. But the University still needed to replace the 64-year-old boiler and 28-year-old cogeneration system located inside the central heating plant, located on the west end of campus, near Oakwood Street.

Three Key Benefits Of Cogeneration

EMU has secured several accolades for the comprehensive energy upgrades implemented during the first phase, including an Energy Efficiency Project Award from the Energy Services Coalition and recognition as one of the nation’s top green colleges by the Princeton Review.

ENGIE Services U.S. is a national energy company that works with educational, government, commercial, industrial and other organizations. Delivers integrated programs that drive sustainable results. Over the past 40 years, ENGIE Services U.S. has provided more than $2 billion in savings to its clients. For more information, visit the company website link. For further details on ENGIE Services’ US relationship with EMU, see the case study link.

Founded in 1849, Eastern is the second oldest university in Michigan. It currently serves more than 20,000 students pursuing undergraduate, graduate, specialist, doctoral, and graduate degrees in the arts, sciences, and professions. In all, more than 300 majors, minors, and concentrations are offered through the university’s faculties of arts and sciences; Business; Education; Health and social services; Technology and its graduate school. EMU is regularly recognized by national publications for its excellence, diversity and commitment to applied education. For more information about Eastern Michigan University, visit the University’s website.

Engage@EMU, GameAbove and the Ypsilanti Downtown Development Authority are teaming up for a new “Explore Ypsi” digital gift card program.

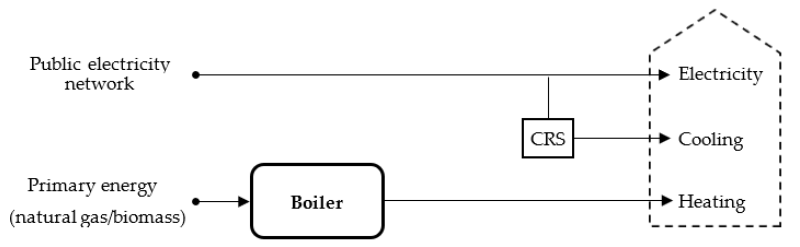

Cogeneration & Trigeneration

Eastern Michigan University’s GameAbove College of Engineering and Technology participates in Automobili-D, part of the North American International Auto Show. Cogeneration is a more efficient use of fuel or heat, because the otherwise wasted heat from electricity production is used for productive purposes. Combined heat and power (CHP) plants recover otherwise lost thermal energy for heating. This is also called combined heat and electricity district heating. Small cogeneration plants are an example of decentralized energy.

The high temperature heat supply first drives a gas or steam turbine generator. The resulting low-temperature waste heat is used for water or space heating. On smaller scales (usually below 1 MW) gas or diesel engines can be used. Cogeneration is also common with geothermal power plants because they often produce relatively low-level heat. Binary cycles may be necessary to even achieve acceptable thermal efficiency for electricity generation. Cogeneration is less commonly used in nuclear plants because NIMBYs and safety considerations have often kept them further from population centers than comparable chemical plants, and district heating is less efficient in less populated areas due to transmission losses.

Cogeneration was practiced in some of the earliest electrical installations. Before central stations distributed power, industries that produced their own power used exhaust steam for process heating. Large commercial and residential buildings, hotels and shops usually produced their own energy and used waste steam to heat the buildings. Because of the high cost of early purchased power, these CHP operations continued for many years after utility electricity became available.

Masnedø CHP power plant in Dmark. This station burns straw as fuel. Adjacent greenhouses are heated by remote heating from the plant.

High Profile: March 2023 By High Profile

Many process industries, such as chemical plants, oil refineries, and pulp and paper mills, require

Risk management in educational institutions, performance appraisal in educational institutions, leadership in educational institutions, public relations in educational institutions, educational institutions in dubai, six sigma in educational institutions, educational institutions in singapore, educational institutions in, jobs in educational institutions, educational institutions in usa, management in educational institutions, educational institutions in andhra pradesh