Cogeneration And Combined Heat And Power (chp) Systems: Maximizing Efficiency – Heat production accounts for half of the world’s last energy consumption and accounts for 40% of global carbon dioxide (CO₂) emissions. It is also a major cause of CO₂ emissions in industry.

What is heat dissipation? Heat dissipation, also known as heat transfer, is a process for reducing CO₂ emissions from heat production. As a first step, this can be achieved by making fuel consumption more efficient. This fossil fuel can later be replaced by carbon-free fuel. On the other hand, heat generation can also be electrified using energy from renewable energy. Existing heating networks can be quickly and large-scale transformed into efficient and flexible low-carbon power systems.

Cogeneration And Combined Heat And Power (chp) Systems: Maximizing Efficiency

There are many programs that can help you to decarbonize the heating network. At Siemens Energy, we provide customized CHP and Power to Heat (P2H) solutions for the residential, commercial or industrial sectors.

Power Plant 3

CHP generates electricity and heat from a single fuel source. Traditional heating plants emit different amounts of CO

Emissions of nearly 50%. In addition, the conversion of the plant into a GT-powered CHP or hybrid power plant with heat extraction can significantly increase its electrical efficiency. As a result, fuel efficiency can be as high as 90% while using as little fuel as possible.

Emissions and eliminate the need for fossil fuels in gas turbines. This is an effective way to clarify the future of a combined power plant and extend its life cycle. Find out how much carbon reduction you can make by burning green hydrogen in your gas turbine. Calculate your carbon dioxide (CO)

P2H can be achieved through heat pumps or electric boilers. The heat pump uses waste or environmental heat to increase its temperature with an electric current. They produce the same heat using less electricity than electric boilers, leading to lower operating costs. Electric boilers require minimal capital and are quick to install. Innovative induction-based technologies or turboheaters are suitable for industrial processes that require high temperatures.

Pdf) Market And Development Trends In Cogeneration And Combined Heat And Power Plants

Another decarbonization pathway is to convert fossil heat generation by switching to sustainable biomass in a combined heat and power plant. When carbon sequestration and storage (CCS) are added, CHP plants based on biomass or biofuels can be converted into biological energy with carbon capture and storage (BECCS), thus allowing for negative emissions and Simultaneous power generation.

For maximum efficiency, it often makes sense to combine different technologies. In order to make the best choice, there are many factors to consider, such as the required temperature level, the distribution power required, the green electricity price, the availability of waste heat, and the annual heating curve. For example, if you have a lot of renewable energy, it makes sense to consider energy to heat (P2H).

Because most of the factors influencing the choice of technology depend on the location of the heating network, there is no one solution that fits all. However, pre-selection of the appropriate technology is possible based on the temperature level required for the specific application. The matrix below shows the temperature levels that can be achieved using various technologies.

Reconfiguring an existing power plant or heater can make a significant contribution to your carbon footprint. The heating plant can be converted into a power plant and the thermal power plant can be converted into a CHP plant. Alternatively, you can convert the entire heating plant into a power-to-heat application.

Thermodynamic Analysis & Enhancement Of Cogeneration Plant

With our Brownfield Transformation approach, you can transform existing assets in a short period of time into low-carbon environments while reusing existing infrastructure as much as possible.

Power to heat (P2H) systems show a pattern change in the capacity of a low carbon power system. Because heat pumps or steam boilers can be powered entirely by green electricity, it allows the integration of renewable energy sources into the production of thermal energy, which is an important and time-consuming integration.

By adjusting their heat output in response to variations in renewable energy generation, power-to-heat systems can also provide flexibility to the grid. Energy-to-thermal systems convert excess renewable energy into thermal energy that can be used for local or central heating needs and cooling.

Heating networks can play an important role in decarbonizing heat production at an affordable price. Technologies for decarbonize industrial heating and district heating are already available and ready to scale.

Combined Heat And Power: Key Considerations

By switching from a coal-fired or oil-based steam plant to a Gas Turbine powered CHP, it is possible to rapidly reduce carbon emissions. Deep carbon dioxide emissions can be achieved by switching from natural gas to biofuels or hydrogen. Even negative CO

Due to the high coefficient of performance (COP), the heat pump provides low carbon heat. They are completely carbon neutral when powered by completely renewable energy.

Heat can be stored significantly more cost-effectively than electricity. The combination of P2H with CHP stabilizes the energy market. Heat pumps operate well when energy costs are low due to excess renewable energy. When energy prices are high, CHP plants can sell energy efficiently and produce heat at the same time. At the highest heat requirements, the heat pump can be operated in conjunction with a CHP plant.

References Low carbon footprint The many advantages of P2H and CHP make it an ideal solution for a greater number of possible applications. See how businesses around the world benefit from Siemens Energy products, from geothermal in Sweden or Germany to textile production in Mexico. What is CHP? Benefits of CHP When to consider CHP? CHP carbon tax improves financial efficiency Can CHP continue? Where to install CHP? CHP Setup Type CHP Planning Considerations CHP Asset-Care Considerations Specify CHP Suppliers

Overview Of Chp (combined Heat & Power)

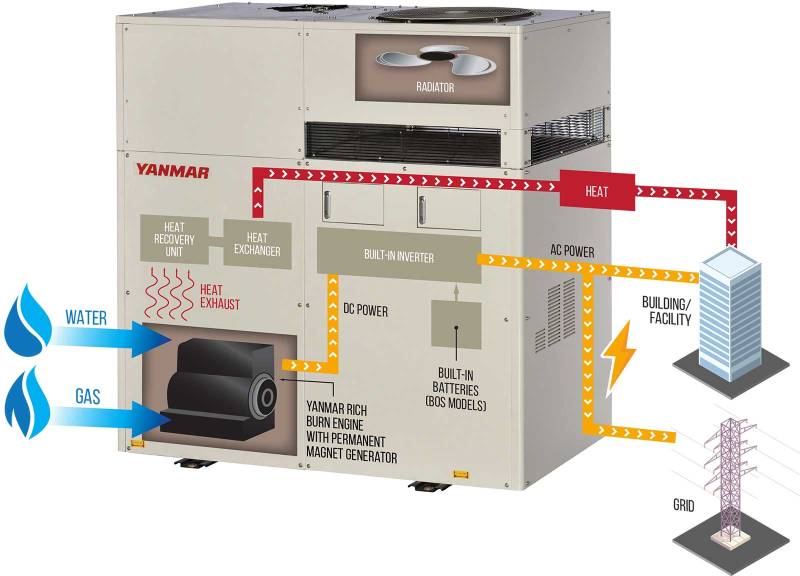

Combined Heat and Power (CHP) or Cogeneration (Cogen) is a well-established technology that generates electricity and heat simultaneously from the fuel injection.

Cogeneration can save up to 30% on energy costs compared to purchasing electricity separately from the grid and gas for use in the on-site boiler.

CHP has been used for many years worldwide, across various industries in various forms (steam boilers and steam turbines, gas turbines, steam boilers and steam turbines, steam engines and heat recovery systems). Selected arrangements are generally found by fuel sources with market segments and scale.

In the United Kingdom, after the privatization of British gas in 1986 and the signal for gas in the 1990s, CHP in the industry increased rapidly with the installation of gas turbines and steam mills, and in the commercial and Hospital with gas engine installation. . Today, due to the reduction of plant size and the need for greater operational flexibility, CHP gas engines have become the leading technology of choice.

Defining Small Scale Combined Heat And Power

With a push towards zero-carbon economic sustainability, all major manufacturers have variations of green biogas and biomethane gas engines and are presenting future proofs of their technology in the use of hydrogen (hybrid or pure).

CHP is a proven technology that can provide up to 95% generation efficiency using low carbon natural gas as a fuel source. As the gas grid turns green, the CHP carbon signature will decrease. However, CHP can use zero carbon fuel directly to provide zero or negative carbon locations.

When businesses are planning to build new equipment or upgrade existing ones, they should consider CHP or Trigeneration, also known as Combined Cooling Heat and Power (CCHP). CHP can play a vital role in supporting businesses to provide sustainable, secure and flexible energy solutions.

The source of fuel (fossil or renewable) is burned and the energy produced is used to drive the primary converter (inverter or gas turbine) which produces mechanical and thermal energy. Mechanical energy is converted into electricity through alternators, and heat can be used directly or converted to meet site requirements.

Micro Cogeneration, Making $ense

For some applications, CHP systems can achieve up to 95% power consumption, typically they meet between 70-80%, which is a significant improvement on power grid imports and normal heat generation. Improving energy efficiency, reducing production costs, and where carbon is used as fuel, it generates a lower carbon footprint per unit of energy produced.

Further energy efficiency is achieved due to the electricity and heat generated and consumed on site, avoiding the transmission loss of about 7.5% that occurs in the transmission of electricity from remote generators to consumers.

Price differences between and depending on the specific needs of the CHP website can provide improvements in energy efficiency, reduction of energy costs, and improvements in carbon signatures. Depending on the fuel source used (e.g., hydrogen biogas), CHP may provide a neutral or negative position of the carbon.

Where the site has low heat requirements but requires cooling for operation, users can introduce refrigeration into their CHP plant, which can operate at temperatures as low as -5 deg C. This is called Combined Cooling Heat, Power (CCHP) or Trigeneration, which can provide cooling for air conditioners and refrigerators.

Combined Heat And Power 101

The term Quadgeneration is given to CHP with the integration of devices that remove exhaust gases and process them to meet the user requirements of specific uses. For growers, this can be a detoxification and cooling gas, while the food and beverage industry requires 99.99% CO.

In your operations and processes then CHP, Trigeneration, or Quadgeneration should be considered as part of the energy strategy.

Combined heat & power chp, combined heat and power chp systems, cogeneration combined heat and power, chp cogeneration systems, cogeneration heat and power, combined heat and power systems, combined heat power systems, micro combined heat and power systems, combined heat and power chp, combined heat and power systems definition, what is combined heat and power systems, chp combined heat and power plant